VMware and Intel are getting ready to demonstrate a scalable, manageable edge compute solution for manufacturing at Hannover Messe 2023. See us at VMware booth F59 in Hall 15 to find out more.

The manufacturing environment has become complex, integrating diverse systems to create competitive products. At the same time, to improve productivity and quality, manufacturers need to use real-time data intelligently to increase quality, efficiency, and ultimately profitability. This requires a new approach to managing the systems and connecting the data.

What software-defined manufacturing needs

Software-defined manufacturing enhances productivity at the edge by connecting devices in the factory, from sensors to cameras to robots. Software-defined industrial solutions reduce hardware footprint at the shop floor by combining workloads. By leveraging standard industrial compliant compute-hardware, agility increases while cost decreases. The increased flexibility and manageability of the workloads enables the management of operational technology (OT) environments with IT tools.

Industrial devices have very specific OT needs. While operating at high speeds, they must be safe, secure, and repeatable. This requires low-latency connectivity, the use of artificial intelligence, and quick analysis of large amounts of data to operate those devices within strict operational, safety, and security standards.

Real-time applications demo

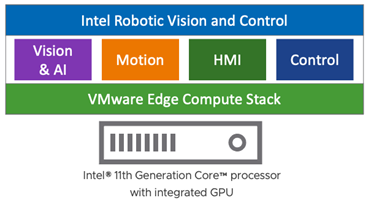

VMware and Intel have worked together to consolidate the critical and non-critical workloads, including AI and computer vision, all deployed on a scalable and manageable edge compute cluster. VMware Edge Compute Stack is used to manage and orchestrate the workloads to the operational requirements. High-speed robotics with enhanced cameras leverage Intel OpenVINO to identify objects in real time and produce an action from the data.

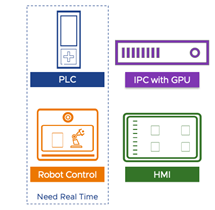

Before: Multiple systems and interfaces

Before the computer-vision solution, four different hardware systems are needed:

- Robot control system

- Programmable Logic Controller (PLC) to control the conveyer belts

- Industrial personal computer (IPC) with a graphics processing unit (GPU) for computer vision

- Human Machine Interface (HMI)

After: One consolidated system on a single edge-compute cluster

After the solution, four hardware systems are consolidated on a single edge compute cluster, running real-time and standard workloads concurrently.

Available today

This robotic solution enables many use cases that improve factory efficiency and output, from quality assurance to defect detection. Intel and VMware are excited to demonstrate a system that you can obtain today through our extensive ecosystem of partners using Intel Architecture and VMware Edge Compute Stack.

Benefits of software-defined manufacturing

- Increase flexibility and manageability by using software-defined functionality.

- Transform operations at the manufacturing edge with a software-defined approach leveraging purpose-built solutions.

- Extend the power of IT automation and software-defined capabilities to OT applications and infrastructure.

- Improve uptime by replacing manual updates and processes on OT equipment with IT manageability functions.

Learn more

- Visit the VMware Edge Compute Stack web page

- Find out how Intel powers industrial robotic arms on the Intel web page